LEADERS IN AUTOMATED PRODUCTION SYSTEMS AND INDUSTRIAL ENGINEERING SERVICES

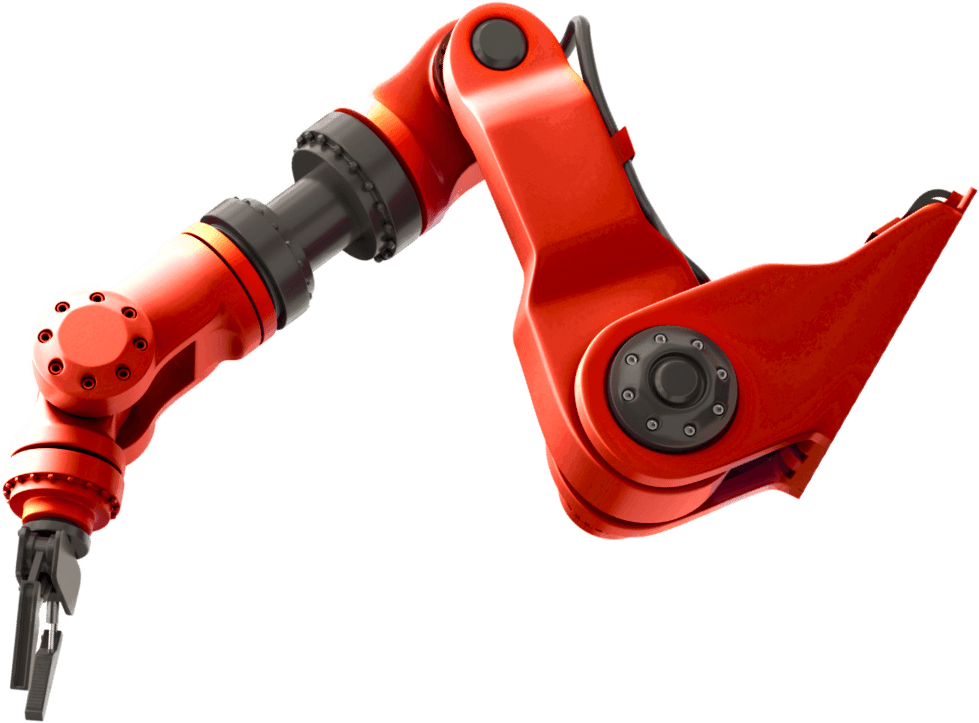

LEADERS IN AUTOMATED PRODUCTION SYSTEMS AND INDUSTRIAL ENGINEERING SERVICESAn industrial engineering firm with over 25 years of experience, MEPEQ helps businesses upgrade their facilities’ shop floors, automate end-of-line processes, and modernize intralogistics with advanced technologies.

WHY US?

WHY US?We enhance your factory’s efficiency through an optimal blend of mechanics, robotics, and human expertise. Our world-class engineers and technicians are dedicated to developing customized, high-performance systems for your shop floor, adopting a systematic, adaptive, and collaborative approach in our processes.

Whether managing projects from start to finish or focusing on specific segments, we consistently maintain international standards, delivering top-quality outcomes every time.

We serve businesses in Dubai, Tbilisi, Beirut, Baghdad, Riyadh, Cairo and many other cities in the MENA region.

WHAT WE OFFER

WHAT WE OFFER OUR ARTICLES

OUR ARTICLESChoosing the right labelling machine is not about picking the fastest option; it’s about finding the best fit for your production needs. With so many options available, it’s easy to assume that rotary labelers are always superior. But how many bottles per hour is only one factor in a much larger equation that includes flexibility, maintenance, changeovers, footprint, label application capability, and total cost of ownership (TCO).

our locations

our locations

Beirut

Contact Number

+961 1 691 850

info@mepeq.com

Address

Horsh tabet facing dolphin building Building 247

Tbilsi

Contact Number

+995 511 229 900

info@mepeq.com

Address

Babutsidze 14, Samgori, Postal code 0145, Zip code 0162, Tbilisi, Georgia

Dubai

Contact Number

+971 50 392 7847

info@mepeq.com

Address

Business Center, Dubai World Central, POBox 39066, Dubai, United Arab Emirates

Riyadh

Contact Number

+966 53 966 2723

info@mepeq.com

Address

7933, King AbdulAziz Road, Adh Dhubbat District, Unit # 220, Riyadh 12623-3921, Riyadh, Saudi Arabia

Baghdad

Contact Number

+964 782 786 7066

info@mepeq.com

Address

Coral Compound, Al-Jadriya, Baghdad, Iraq

Cairo

Contact Number

+20 10 2247 8333

info@mepeq.com

Address

Teseen St, New Cairo 1

Customers

Customers Register to our Newsletter

Register to our Newsletter Solution Partners

Solution Partners Strategic Partners

Strategic Partners Join our team

Join our teamWant to join our team of engineers, technicians and robotics lab?

If you think you got what it takes, fill out the form and we will contact you within a few days in order to discuss more.